Getting your boat to the water is the first step of any great day. It relies entirely on a well-maintained trailer. Ignoring your trailer can lead to dangerous breakdowns, costly repairs, or damage to your prized vessel.

This guide breaks down critical boat trailer maintenance tips into six essential areas. We provide actionable, step-by-step instructions to ensure your trailer is as seaworthy as your boat. Following these practices will enhance safety and protect your investment.

From inspecting tires to checking bearing lubrication, we cover the essentials that keep you rolling safely. We will explore everything you need to know about your trailer’s lighting, winch, and frame. Proactive maintenance is key to avoiding a ruined weekend.

Think of your trailer as an extension of your towing vehicle; it deserves the same care. Beyond these checks, understanding the benefits of managing vehicle maintenance can extend its life. This guide will equip you with the knowledge to handle these tasks confidently.

1. Regular Tire Inspection and Maintenance

Your boat trailer's tires are the unsung heroes of every trip to the water. They support heavy loads and then experience rapid temperature shock when submerged in cool water. This combination of stress makes diligent tire care one of the most critical boat trailer maintenance tips.

Ignoring your trailer tires can lead to catastrophic failure on the highway. Unlike car tires, trailer tires often fail from age, environmental degradation, and improper inflation. A proactive, consistent inspection routine is essential.

Why Trailer Tires Need Special Attention

The life of a boat trailer tire is uniquely challenging. They are often designated as "Special Trailer" (ST) tires, engineered for vertical loads and high stress. Their construction differs from standard passenger tires, with stiffer sidewalls to reduce sway.

Consider these factors:

- Load and Inactivity: Trailer tires bear the full weight of your boat, often sitting idle for weeks. This prolonged pressure can create flat spots and weaken the internal structure.

- Environmental Exposure: From saltwater corrosion to intense UV radiation, the rubber compounds are constantly under attack. This leads to dry rot and sidewall cracking, a common cause of blowouts.

- Wear Patterns: Rigid trailer suspension can cause tires to bounce on bumpy roads. This can lead to uneven wear that signals suspension or balance issues.

Expert Insight: Marina operators consistently report that most roadside assistance calls are for tire-related failures. A simple monthly inspection can dramatically reduce your risk.

Your Essential Tire Maintenance Checklist

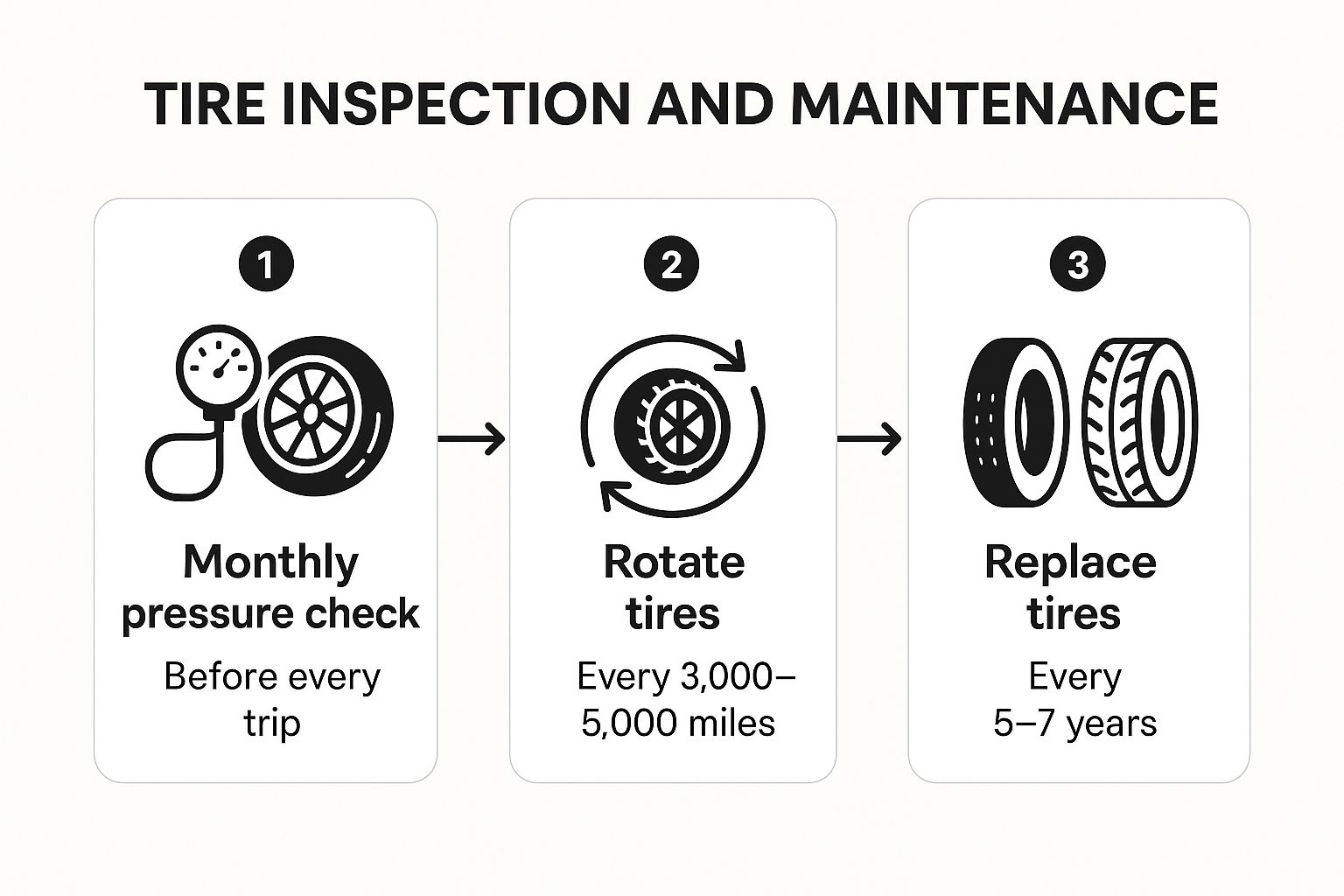

To keep your trailer rolling safely, integrate these steps into your routine. The following process flow diagram illustrates the foundational cycle of effective tire care.

This visual guide highlights a simple three-part strategy. Frequent pressure checks, routine rotation, and time-based replacement form the cornerstone of tire safety. Following this process is one of the most effective boat trailer maintenance tips.

- Check Pressure Before Every Trip: Use a quality pressure gauge to check tires when they are cold. Inflate them to the maximum PSI indicated on the tire's sidewall.

- Inspect for Damage: Before each use, walk around the trailer and visually inspect each tire. Look for cracks, bulges, or embedded objects on the inner and outer sidewalls.

- Rotate Seasonally: Rotate your tires every 3,000-5,000 miles or at the beginning of each boating season. This is also a good time to check your spare.

- Replace Based on Age: Trailer tires should be replaced every 5 to 7 years, regardless of tread depth. Check the tire's DOT code to determine its manufacturing date.

- Store Properly: During the off-season, use tire covers to protect them from UV rays. Consider placing the trailer on jack stands to take the weight off the tires completely.

Even with meticulous care, flats can happen. A comprehensive mobile tyre fitting guide can be an invaluable resource. It explains how to get professional help delivered right to your driveway.

2. Bearing Maintenance and Replacement

Wheel bearings are the critical connection between your trailer's axle and its wheels. They operate in a harsh environment, enduring highway speeds followed by immediate submersion in water. This makes diligent bearing maintenance one of the most vital boat trailer maintenance tips.

Neglecting your wheel bearings can lead to disaster. A seized bearing can cause the wheel to lock up or detach from the axle at highway speeds. The difference between a smooth trip and an emergency often comes down to marine-grade grease and a consistent inspection.

Why Trailer Bearings Need Special Attention

The life of a boat trailer bearing involves extreme stress and contamination risk. When a hot hub is submerged in cooler water, the air inside cools and contracts. This creates a vacuum that actively pulls water and contaminants past the seals.

Consider these factors:

- Thermal Shock: The rapid temperature change from driving to launching creates a vacuum effect. This makes water intrusion a constant threat.

- Corrosion: Even a small amount of water, especially saltwater, inside the hub will emulsify the grease. This causes rapid rust and pitting on bearing surfaces.

- Heavy Loads: Bearings support the static weight of the boat during storage and dynamic loads while traveling. This leads to eventual wear and fatigue.

Expert Insight: Many professional fishing guides make bearing repacking an annual ritual. They recognize that proactive service is far cheaper and safer than dealing with a failed hub miles from home.

Your Essential Bearing Maintenance Checklist

A proactive approach is the key to bearing longevity and on-road safety. Integrating these checks into your routines will dramatically reduce your risk of failure. This video from Dexter Axle Company provides a clear visual guide.

Following a methodical checklist ensures no step is missed. This is a cornerstone of effective boat trailer maintenance tips.

- Feel the Hubs: After a short tow, carefully touch each wheel hub. If one is much hotter than the others, it signals a potential bearing problem.

- Check for Play: Before each trip, jack up each wheel and grasp it at the top and bottom. Any significant play or "wobble" signals a worn or loose bearing.

- Listen for Noise: While towing, listen for any grinding, humming, or rumbling sounds from the wheels. These noises are classic indicators of a failing bearing.

- Annual Repacking: At a minimum, repack your bearings with high-quality marine-grade grease annually. This forces out old grease and replenishes the lubrication.

- Install Bearing Protectors: Use spring-loaded bearing protectors to maintain positive pressure inside the hub. This helps prevent water intrusion during launching.

- Carry a Spare: For any long trip, always carry a complete spare hub or bearing kit. This small preparation can save your entire trip.

3. Brake System Inspection and Service

Your trailer's brake system is a critical safety net for controlling your combined vehicle and boat. Whether you have electric or hydraulic brakes, their reliable function provides necessary stopping power. The marine environment is uniquely destructive, making brake care one of the most vital boat trailer maintenance tips.

Neglecting your trailer's brakes can lead to dangerously increased stopping distances or complete system failure. Unlike a car's sealed system, trailer brakes are frequently exposed to the elements. Proactive inspection and regular servicing are essential for safe towing.

Why Trailer Brakes Need Special Attention

The life of a boat trailer brake system is a constant battle with water and corrosion. Both surge and electric systems have unique vulnerabilities that require diligent maintenance. Even the most robust components rely on the owner for proper care.

Consider these factors:

- Corrosion and Seizure: Saltwater is the primary enemy. It rapidly corrodes steel brake lines, calipers, and electrical connectors, causing parts to seize.

- Water Intrusion: Launching and retrieving your boat submerges the brake system. This water can contaminate brake fluid or short out electrical connections.

- Operational Stress: The brakes must manage the entire weight of the boat and trailer. This generates immense heat and stress, especially during highway travel.

Expert Insight: Boaters in coastal areas often flush their brake system with fresh water after every single launch. This simple, five-minute task can prevent catastrophic corrosion and add years to component life.

Your Essential Brake Maintenance Checklist

To ensure your trailer stops reliably, integrate these steps into your routines. A functional brake system is a cornerstone of safe trailering. It protects you, your investment, and others on the road.

A thorough check of the actuator, brake lines, and wheel components is a core part of effective brake maintenance. Following this process is one of the most important boat trailer maintenance tips for safety.

- Test Before Each Trip: In a safe area, test the brakes to ensure they engage smoothly. For electric brakes, manually activate the controller; for surge brakes, perform a few slow, firm stops.

- Flush After Every Saltwater Dip: Use a hose to thoroughly rinse all brake components with fresh water. This is the single most effective way to combat corrosion.

- Check Fluid Levels and Lines: For hydraulic systems, check the master cylinder fluid level monthly. Visually inspect all brake lines for cracks, leaks, or corrosion.

- Inspect Electrical Connections: On electric brake systems, check all wiring for frays or damage. Apply marine-grade dielectric grease to prevent corrosion.

- Perform Annual Service: At least once a year, pull the hubs to inspect brake shoes, pads, and hardware. Replace parts if they are worn or contaminated with grease or fluid.

4. Lighting System Maintenance

Your trailer's lighting system is a critical safety feature, ensuring you are visible to other drivers. These systems endure a brutal existence, exposed to moisture, vibration, and corrosion. A malfunctioning light is a safety hazard and a common reason for a traffic stop.

Neglecting your trailer lights can lead to dangerous situations. The electrical components are uniquely vulnerable to the cycle of submersion and drying. This is why consistent lighting system checks are among the most vital boat trailer maintenance tips.

Why Trailer Lighting Needs Special Attention

The life of a trailer's electrical system is a constant battle against the elements. A trailer's harness is often exposed, and the lights themselves are designed to be submersible. Modern, sealed LED lights have improved reliability, but are not immune to wire damage.

Consider these factors:

- Submersion and Corrosion: Rear lights are repeatedly dunked in water. This can corrode bulb sockets, wiring, and plug connections.

- Vibration and Wire Fatigue: Constant road vibration can cause wires to chafe against the trailer frame. It can also cause incandescent bulb filaments to break.

- Grounding Issues: A poor ground connection is a frequent culprit for lighting problems. Rust on the trailer frame where the ground wire attaches can interrupt the entire circuit.

Expert Insight: Many frequent boaters install quick-disconnect plugs for their rear light bars. This allows them to remove the lights before backing into the water, eliminating water damage risk.

Your Essential Lighting Maintenance Checklist

A proactive approach is the best way to ensure your lights work every time. Integrating these simple checks into your pre-trip routine will prevent most common electrical issues. This will keep you safe and legal on the road.

- Test Before Every Trip: Connect the trailer and turn on the lights. Systematically check the running lights, brake lights, and both turn signals.

- Apply Dielectric Grease: At the start of each season, apply dielectric grease to the electrical plug contacts. This displaces moisture and prevents corrosion.

- Inspect and Secure Wiring: Visually trace the wiring harness from the plug to the lights. Look for frayed wires and secure them to the frame with zip ties.

- Carry Spares: Keep a small kit with spare fuses and a few spare bulbs. Even with reliable LEDs, a faulty fuse can leave you in the dark.

- Upgrade to LEDs: If you have older incandescent lights, consider upgrading to sealed LED units. They are more resistant to vibration and water, last longer, and are brighter.

Properly functioning trailer lights are just as important as boat lights. For more information on marine electrical systems, an article about running lights on a boat can offer related insights.

5. Winch and Safety Chain Inspection

The trailer winch and safety chain are your boat's primary lines of defense during transport. These components are subjected to immense stress from road travel and braking forces. Diligent inspection is non-negotiable, as a failure can lead to the boat shifting or detaching.

Neglecting the winch and chains is a significant gamble that can result in catastrophic damage. Leading manufacturers like Fulton Performance Products engineer their systems for strength. However, even the best equipment requires regular maintenance to counteract wear and corrosion.

Why Your Winch and Chains Demand Attention

The winch strap or cable and safety chains are under constant tension and exposed to harsh elements. The stress they endure is dynamic, with every bump on the road testing their integrity. Understanding these challenges highlights why routine checks are so important.

Consider these factors:

- Material Fatigue: Winch straps can degrade from UV exposure, becoming brittle. Steel cables can develop broken strands and internal rust.

- Mechanical Wear: The gears and brake mechanisms inside the winch can wear down or seize. A failing brake could release the winch under load.

- Chain and Hook Integrity: Safety chains and their hooks can rust, crack, or become bent. A weak link is all it takes for the entire system to fail.

Expert Insight: Insurance companies often investigate securing systems after an accident. A claim could be denied if evidence of poor maintenance is discovered.

Your Essential Winch and Safety Chain Checklist

Integrating a few quick checks into your routine will ensure your boat remains securely fastened. This process safeguards your investment and enhances your safety. It confirms every part of your securing system is ready for the road.

- Inspect the Strap or Cable Monthly: Unspool the winch strap or cable and inspect its entire length. Look for fraying on straps, and check for broken strands or corrosion on cables.

- Lubricate Winch Mechanisms: At least once per season, lubricate the winch gears, shaft, and handle. This ensures smooth and reliable operation.

- Test the Winch Brake: Before each trip, engage the winch's locking mechanism. Give a slight pull on the strap to confirm it holds fast.

- Check Safety Chains and Hooks: Ensure chains are crossed under the trailer tongue and attached securely. They should have enough slack for turns but not drag on the ground.

- Replace When Worn: Plan to replace winch straps or cables every 3-5 years. Replace them immediately if you find any significant damage.

- Secure the Winch Handle: Always use a winch handle keeper or ensure the handle is locked. Many boaters have lost their winch handle at the launch ramp.

6. Frame and Tongue Rust Prevention

Your trailer's frame and tongue are its backbone, providing essential structural support. This metal skeleton is constantly under attack from moisture, road salt, and saltwater. Proactive rust prevention is one of the most vital boat trailer maintenance tips to prevent structural failure.

Failing to address rust can lead to weakened welds and a trailer that is unsafe to tow. Frame rust can develop unnoticed in crevices, joints, and on the underside. A dedicated inspection and prevention strategy is essential.

Why Your Trailer Frame is So Vulnerable

The life of a trailer frame is a constant battle against oxidation. Whether painted steel or galvanized, the protective coating is its only defense. Once that barrier is breached, the rusting process begins.

Consider these factors:

- Constant Wet/Dry Cycles: Launching and retrieving your boat subjects the frame to repeated submersion. This traps moisture in hidden areas.

- Salt Exposure: Trailers used in saltwater or on treated winter roads are exposed to highly corrosive salts. These dramatically accelerate rust formation.

- Flex and Stress: The frame and tongue flex under load. This can cause micro-fractures in coatings, creating entry points for moisture.

Expert Insight: Many commercial marine operators schedule annual applications of rust-inhibiting coatings. They understand that preventing rust is far cheaper and safer than repairing a compromised frame.

Your Essential Frame Maintenance Checklist

A simple but consistent routine is key to keeping corrosion at bay. Integrate these steps into your maintenance schedule. This is especially important after trips to saltwater or at the end of the season.

- Rinse After Every Use: Thoroughly wash the entire frame with fresh water after every launch. Pay close attention to rinsing inside C-channels where salt can accumulate. Given this, consult a vehicle salt removal guide to bolster your efforts.

- Inspect and Touch-Up: Regularly inspect the frame for paint chips, scratches, or bubbling. Immediately sand the area, apply a marine-grade metal primer, and touch it up with paint.

- Apply a Rust Inhibitor: Annually apply a penetrating rust-preventive oil or coating. Spray it liberally into joints, crevices, and inside frame rails.

- Check Welds and Stress Points: During your inspection, examine all welds and high-stress areas. Look for any signs of cracking or advanced rust.

- Consider Sacrificial Anodes: If you operate exclusively in saltwater, consider installing sacrificial zinc anodes. These will corrode first, protecting the steel frame.

Protecting the frame is a core element of safe towing. For a broader understanding of best practices, you can review these tips for trailering a boat.

Boat Trailer Maintenance Tips Comparison

| Item | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Regular Tire Inspection and Maintenance | Moderate 🔄🔄: Monthly checks, seasonal rotation | Moderate ⚡⚡: Requires tire pressure gauge, replacement tires | High 📊📊📊: Fewer blowouts, improved fuel efficiency | All boat trailers, frequent launching/storage | Prevents blowouts, extends tire life, improves stability |

| Bearing Maintenance and Replacement | High 🔄🔄🔄: Specialized tools, labor-intensive | High ⚡⚡⚡: Marine-grade grease, bearing protectors, replacement parts | Very High 📊📊📊📊: Prevents wheel failure, extends axle life | Saltwater use, high-launch frequency | Prevents catastrophic failure, improves towing efficiency |

| Brake System Inspection and Service | High 🔄🔄🔄: Requires expertise, electrical/hydraulic systems | High ⚡⚡⚡: Brake controllers, hydraulic fluid, replacement components | Very High 📊📊📊📊: Shorter stopping distances, safer towing | Heavy trailers, legal compliance | Essential stopping power, reduces tow vehicle brake wear |

| Lighting System Maintenance | Moderate 🔄🔄: Wiring checks, possible professional installation | Moderate ⚡⚡: LED kits, wiring testers, replacement bulbs or fixtures | High 📊📊📊: Improved visibility, legal compliance | Frequent road travel, DOT compliance | LED longevity, corrosion resistance, quick-disconnect ease |

| Winch and Safety Chain Inspection | Moderate 🔄🔄: Monthly inspections, lubrication | Moderate ⚡⚡: Lubricants, replacement cables/chains | High 📊📊📊: Secure boat retention, accident prevention | Boat transport security critical | Positive load retention, long-lasting components |

| Frame and Tongue Rust Prevention | Moderate 🔄🔄: Regular washing and inspections | Moderate ⚡⚡: Rust inhibitors, paint, zinc anodes | High 📊📊📊: Structural integrity, extended trailer lifespan | Saltwater exposure, long-term trailer use | Prevents corrosion, maintains structural safety |

Keeping Your Journey Safe and Smooth

Navigating the world of boating extends far beyond the water's edge. The journey to the boat ramp is an integral part of every aquatic adventure. The reliability of your trailer is the bedrock of that experience.

Mastering these boat trailer maintenance tips is about embracing a proactive mindset. It safeguards your investment, your time, and, most importantly, your safety. Consistent maintenance transforms your trailer from a liability into a trusted partner.

Synthesizing Your Maintenance Strategy

The most effective approach views these tasks as interconnected systems. A failure in one area can quickly cascade into a much larger, more dangerous problem. A cohesive plan is key.

- Tires and Bearings (The Foundation): These components bear the entire load. Check tire pressure before every trip. Make bearing lubrication a post-trip ritual to prevent catastrophic failure.

- Brakes and Lights (The Safety Systems): Your brake and lighting systems are your primary communication tools on the road. A simple pre-trip walk-around to test every light function is a non-negotiable habit. Periodically check brake fluid and actuator.

- Frame and Hardware (The Skeleton): Your trailer's structural integrity is paramount. A thorough freshwater rinse-down after every use is your best defense against rust. Pair this with annual inspections of welds, the frame, and the winch assembly.

From Checklist to Habit: Making Maintenance Second Nature

The true value of these boat trailer maintenance tips is realized when they become an ingrained habit. The goal is to develop an intuitive sense for your equipment’s condition. You start to recognize subtle signs of wear before they become overt problems.

Key Takeaway: Proactive maintenance is not about adding another chore. It is about removing uncertainty and stress from your boating experience.

By dedicating a few minutes before and after each trip, you build a powerful routine. This consistency preserves the value of your boat and trailer and minimizes costly repairs. Your trailer is the unsung hero that makes every trip possible; treat it with the care it deserves.

For more in-depth guides and expert advice, explore the resources at Boating Articles. Our library of informative content is designed to empower you to be a safer, more confident boater. Visit Boating Articles to continue learning today.