If your boat's steering feels mushy or unresponsive, you likely have air in your hydraulic lines. Bleeding the system removes this trapped air. This restores the firm control needed for safe navigation.

Delaying this maintenance can lead to bigger problems. You risk premature helm pump failure. In a worst-case scenario, you could lose steering entirely.

Why Your Steering Feels Spongy and What to Do

Hydraulic systems are not perfectly sealed. Small amounts of air can enter through vents and seals over time. This infiltration can cause poor performance and internal corrosion.

Most experienced boaters recommend bleeding the system every two years. If your hydraulic fluid looks cloudy or milky, you have water contamination. This requires a full fluid flush, not just a simple bleed.

A full fluid flush often needs a follow-up bleed after about 24 hours. The flushing process can introduce microbubbles into the new fluid. These bubbles need time to rise before you can purge them effectively.

Understanding the difference between a bleed and a flush is critical for safe steering. You can find more real-world tips about hydraulic steering maintenance from boating forums. While you're at it, brushing up on other skills like how to tie a boat to a dock is always a good idea.

Gathering The Right Tools For The Job

Before you begin, get your tools organized. Scrambling for a missing tool or more fluid mid-job is frustrating. A little preparation makes the task much smoother.

The most important item is the correct hydraulic fluid. Check your owner's manual for the manufacturer's recommendation, like the common SeaStar HA5430H. Using the wrong fluid can damage seals and cause significant problems.

A dedicated bleeder kit is extremely helpful for this job. These kits typically include a filler tube that screws onto the helm pump. This tool lets you add fluid without introducing more air into the system.

Essential Tools and Supplies Checklist

Use this checklist to ensure you are fully prepared. Having everything ready will help the job go smoothly.

| Item | Specification/Type | Purpose |

|---|---|---|

| Hydraulic Fluid | Manufacturer-specific (e.g., SeaStar HA5430H) | Topping off and replacing old fluid in the system. |

| Bleeder Kit | System-compatible (e.g., SeaStar HA5438) | Simplifies adding fluid and purging air without mess. |

| Wrenches | Box-end wrenches fitting the bleeder nipples | To open and close the bleeder valves on the cylinder. |

| Rags/Paper Towels | Clean and absorbent | For catching drips and cleaning up spills immediately. |

| Waste Container | Old jug or bucket | To collect the old, purged hydraulic fluid for proper disposal. |

| Helper | A patient friend | To turn the steering wheel while you manage the bleeder valves. |

Once you have these items ready, you are set for a clean and successful bleeding process.

A Practical Walkthrough for Bleeding Your System

With your tools ready, it's time to get the air out of the lines. The key to this job is patience. Rushing can introduce more air and make the steering feel worse.

You are looking for a steady stream of clear, bubble-free fluid from the bleeder fittings. This indicates that all the air has been purged from the system.

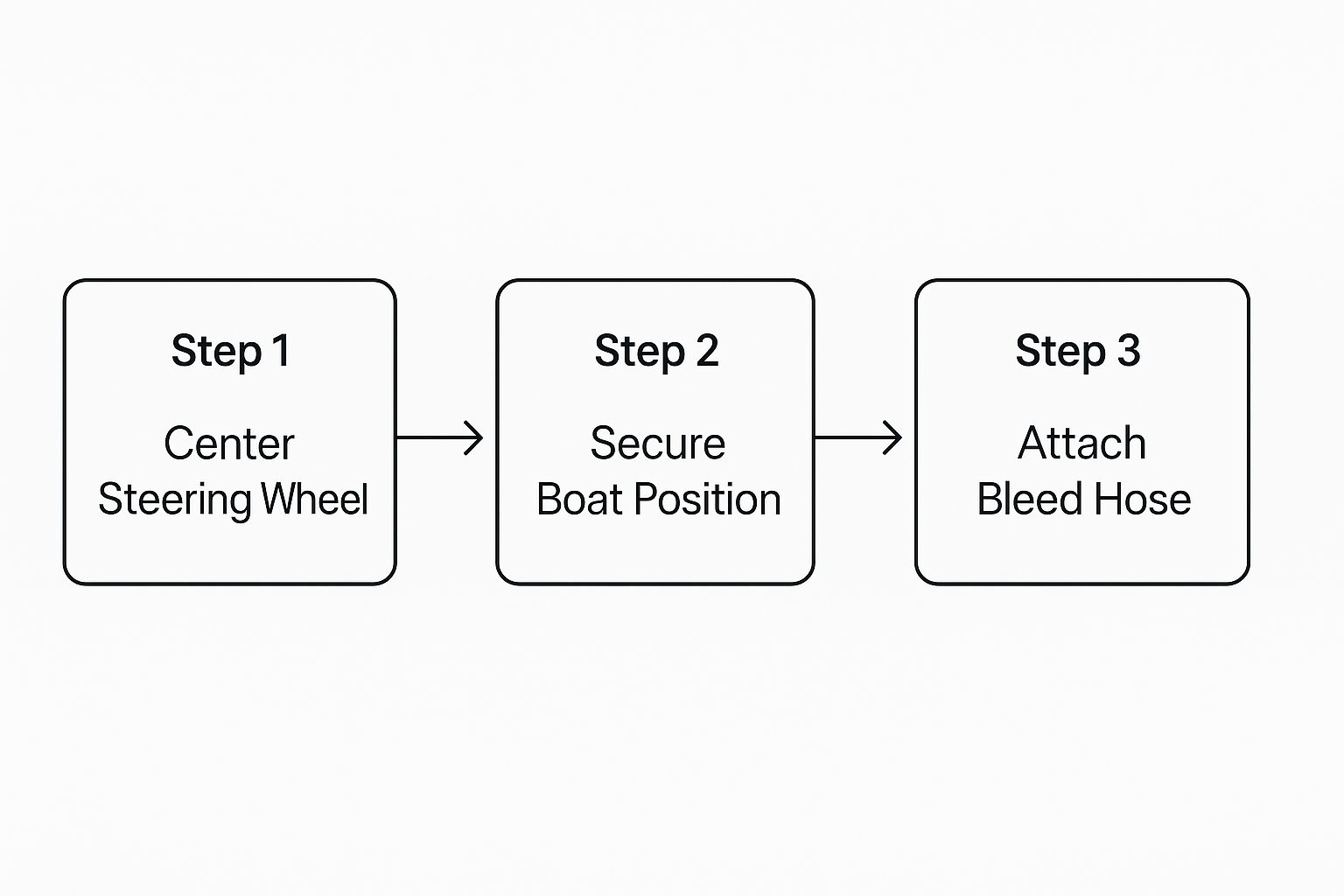

Following the initial setup sequence properly prepares the system. It's a simple but critical first step before you start turning the wheel.

This process can be tedious and may require hundreds of wheel turns. Do not get discouraged if the steering doesn't feel perfect right away. Patience is a necessary part of the process. If you're stuck, you can find helpful insights in this detailed Hynautic steering system debug.

What About Autopilots and Multiple Helm Stations?

Adding an autopilot or a second helm station makes the job more complex. A boat with a flybridge has extra lines and components. Each part can trap air, requiring a more methodical process.

Following the correct sequence is crucial. You must work through the system logically to push all the air out.

A Proven Bleeding Sequence

Here is the order that works best for complex systems:

- Start at the Top: Begin with the helm station that is highest or furthest from the steering cylinder. On a flybridge cruiser, start at the flybridge.

- Move to the Lower Helm: After the flybridge helm feels solid, move to the main helm and repeat the process.

- Finish with the Autopilot: The last component to bleed is the autopilot pump.

Following this "furthest to closest" order is vital. If you bleed out of sequence, you will push air back into lines you thought were clear. This creates a frustrating cycle you can easily avoid.

Hydraulic steering is used on vessels up to 130 feet due to its durability. These systems require proper maintenance to perform correctly. Learning more about advanced hydraulic steering systems for various boats can provide a deeper understanding.

Troubleshooting Common Bleeding Headaches

If the steering still feels soft after bleeding, don't give up. This usually points to a trapped air pocket or a small leak.

Before starting over, check all hydraulic fittings from the helm to the cylinder. Boat vibrations can loosen connections over time.

Pinpointing the Problem

If all connections are tight and the problem persists, consider other culprits.

- Bad Helm Check Valve: A faulty check valve in the helm pump is a common issue. It allows fluid to bypass internally, causing a sloppy feel at the wheel.

- Blocked Bleeder Nipple: If no fluid comes out when you open a bleeder screw, the nipple is likely blocked. This can be caused by old, sludgy fluid or debris.

Sometimes, another slow, methodical bleed will solve the problem. If you suspect a leak, pressurize the system slightly and check every connection for weeping fluid. These steps are similar to what you'd do during seasonal upkeep, which is covered in our guide on how to winterize your boat.

Answering Your Hydraulic Steering Questions

A few questions about hydraulic steering come up often. Let's clear up some of the most common ones.

How Often Should I Bleed My Steering System?

As a general rule, plan to bleed the system every two years. This should be part of your regular maintenance schedule.

You should bleed it sooner if you notice signs of trouble. Spongy steering is a classic symptom of air in the lines. Milky fluid indicates water contamination, which requires immediate attention.

What Kind of Fluid Should I Use?

Always use the specific fluid recommended by your steering system's manufacturer. Check the owner's manual for your model's specifications.

Do not substitute with other fluids like automatic transmission fluid (ATF). The additives in these fluids can damage the seals in your hydraulic system. This can lead to leaks and eventual failure.

Pro Tip: A well-maintained boat runs on more than just a good engine. Our guide on how to pick the right boat propeller can help you improve performance and efficiency.

What’s the Biggest Mistake to Avoid?

The most common mistake is letting the helm pump reservoir run dry during the bleeding process.

If the fluid level drops too low, the pump will suck in air. You will have to start the entire process all over again. Always keep the reservoir topped up.

At Boating Articles, we provide expert guides to keep your vessel in prime condition. Find more DIY projects and informative articles at https://boating-articles.com.